Innovation From Design To Production

Advanced engineering and experienced project teams

Using 3-D design tools, we will develop customized solutions for you, with a focus on cost-effectiveness, ease of manufacture, and process consistency. Our team will share our engineering knowledge and years of experience in metal forming to create a high-quality tool or process at the lowest cost possible.

Tool & Die Product Management

Your assigned Program Manager will also oversee any subcontractors or suppliers involved in your project’s supply chain, should we decide to award subcontracts for additional machinery or processes. They will provide you with regular updates on the project’s status, whether it pertains to prototypes, tool and gage build, or advancements in automated welding, staking machines, or robotic carrying tools.

Following the launch of your product, our Quality Assurance (QA) department will rigorously uphold the highest quality standards during the manufacturing process. This is accomplished through the utilization of cutting-edge Coordinate Measuring Machine (CMM) software and other precise instruments.

We maintain consistent communication with you to facilitate an ongoing process of continuous improvement. If deemed necessary, we will work collaboratively to fine-tune aspects of your product’s design or build to ensure optimal performance and satisfaction.

Prototype / R&D Development Services

In a world that’s constantly evolving, staying ahead of the curve means embracing innovation at every turn. At Diemax, we understand that innovation begins with a spark—an idea, a concept, a vision. Our Prototype and R&D Development services are designed to nurture those sparks and transform them into revolutionary products and solutions. Here’s why Diemax is the launchpad for your next breakthrough

Our commitment doesn’t end with a prototype. We offer end-to-end support, including testing, refinement, and even assistance in transitioning from the prototype stage to full-scale production.

Diemax’s Prototype and R&D Development services are not just about creating products; they’re about shaping the future. We thrive on challenges and take pride in contributing to the next big idea. Your vision, paired with our expertise, can turn possibilities into realities.

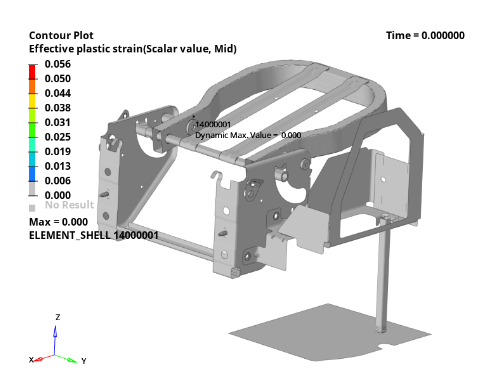

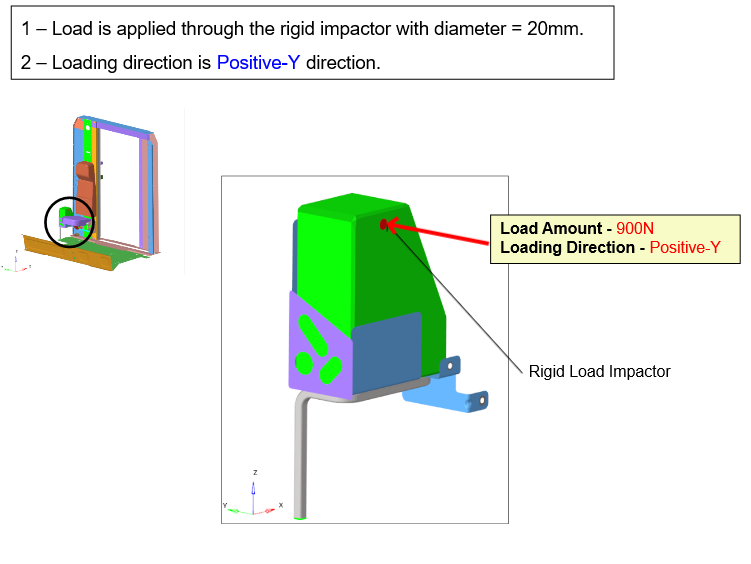

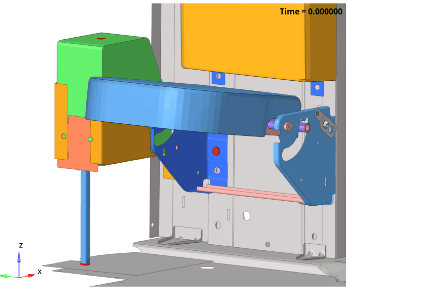

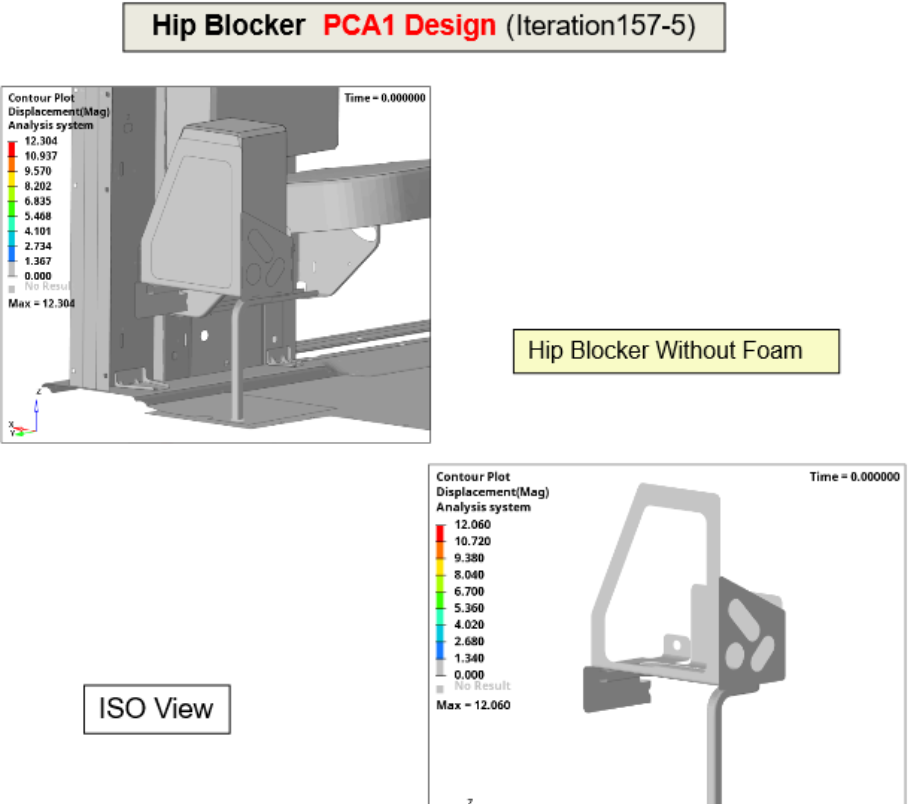

Simulation & Design Services

Our Simulation and Design services are underpinned by the use of advanced 3-D design tools. These tools allow our adept engineers to create highly detailed and precise design plans. These plans serve as the foundation for your product development, ensuring that every component and process is meticulously planned.

We understand that every project is unique, and our approach involves customizing solutions to meet your specific needs. This level of customization allows us to address your particular challenges and goals, whether you’re developing a new product or enhancing an existing one.

The 3-D design tools we employ enable us to create designs that simplify the manufacturing process. This simplicity is valuable in the production phase, reducing the likelihood of errors, speeding up production, and ensuring that the final product aligns with your expectations.

Our approach is geared towards supporting innovation. By providing customized design solutions, we enable you to bring innovative products to life. Whether you’re creating new products or enhancing existing ones, our Simulation and Design services facilitate the process of turning your creative ideas into tangible products.

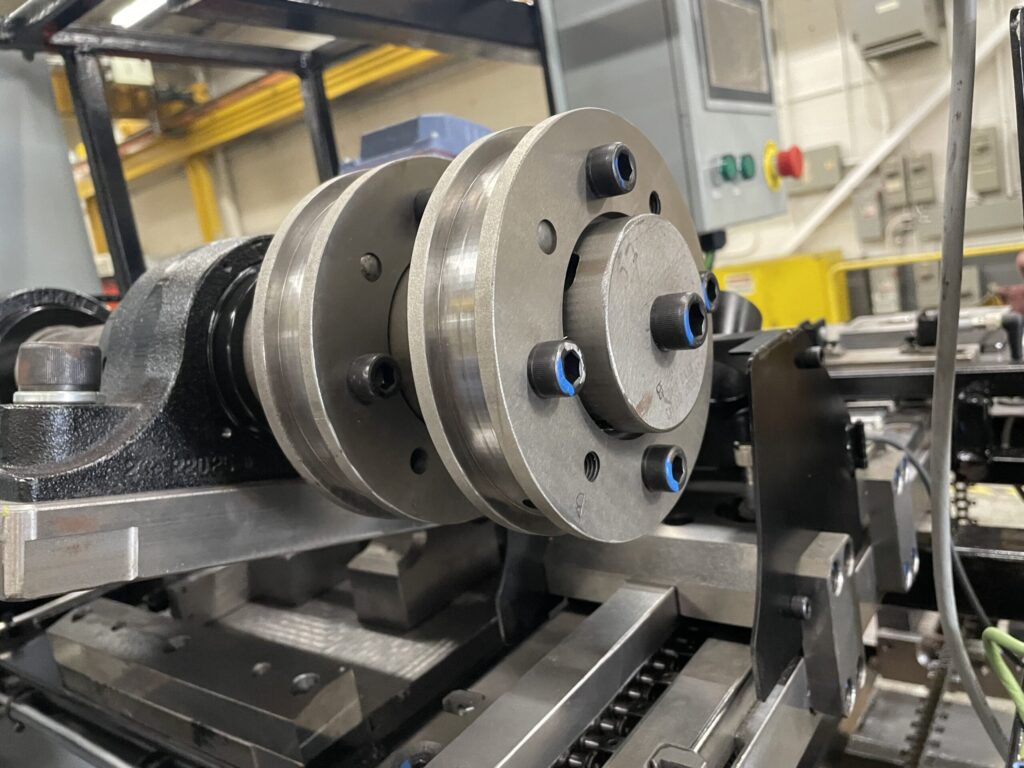

Tooling & Fixture Builds

Each manufacturing process and product is unique, and our approach revolves around creating custom-built solutions that cater to your specific needs. We work closely with you to understand the intricacies of your manufacturing processes and design tooling and fixtures that align perfectly with your requirements.

Tooling and fixtures play a crucial role in enhancing manufacturing processes. They aid in maintaining precision, reducing errors, and speeding up production. By optimizing these aspects, our services help ensure that your products meet or exceed your requirements for quality and consistency.

Our services are designed to support innovation in manufacturing. We understand that staying competitive often requires finding new and efficient ways of producing products. By custom-designing and constructing tooling and fixtures, we enable you to innovate and enhance your manufacturing processes.

Our team of experts collaborates with you to create comprehensive plans for tooling and fixture builds. These plans encompass every detail, from design to production, ensuring that the components are precisely tailored to your manufacturing processes.

Tooling & Fixture Builds

Engineering Changes

Our Engineering Changes services are anchored in agility and adaptability. We understand that projects can evolve, and requirements may change. Our team is well-prepared to swiftly adapt to these changes, ensuring that your project stays on track and ultimately delivers the results you desire.

Implementing engineering changes seamlessly is crucial to minimizing disruptions in the project’s timeline and budget. Our expertise allows us to integrate changes into the existing project structure without causing significant delays or cost overruns.

We recognize the importance of project continuity. Engineering changes are not just about making adjustments; they are about maintaining the project’s momentum and ensuring that it progresses smoothly toward its goals. Our services are designed to support this continuity.

Timeliness is crucial when implementing engineering changes. Our services are designed for swift execution, allowing your project to adapt and proceed without unnecessary delays.